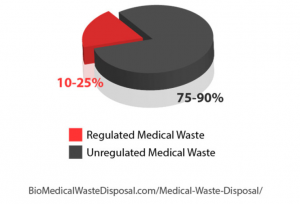

The global medical waste management market is expected to reach $14 billion in 2020. More hospitals and clinics are beginning to realize how important efficient biomedical waste management is.

But more business means more medical waste to dispose of safely. In the United States alone, we already produce 13 pounds of medical waste per person every year.

The need for more efficient biomedical waste solutions has never been greater. And that starts with advancements in biomedical waste management.

Here are the trends to watch to make sure you’re staying on top of a quickly changing industry.

Energy Conversion

One of the best ways to make biomedical waste management a more environmentally-friendly process is to harness the energy it can produce.

A study about converting medical waste into energy makes a compelling case about the future of biomedical waste management.

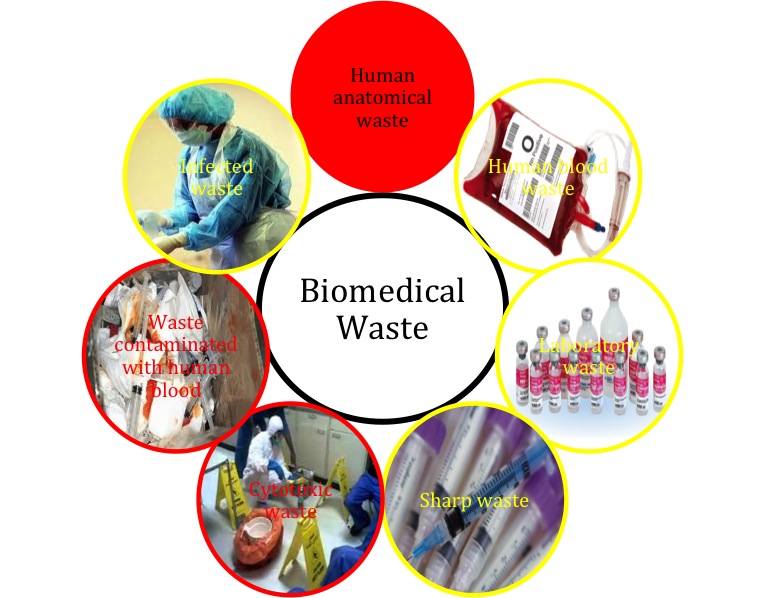

The study claims that two key elements of a good deal of biomedical waste. It says blood and saliva can be converted into energy if you use the right technology.

Converting Glucose into Energy

These biological fluids contain glucose, which can be converted into the energy used to generate electricity. Glucose is how our bodies break down carbohydrates to harness energy for our bodies. It’s why eating helps keep us energized.

Glucose can be used to generate electricity in much the same way. In the study, a prototype was developed that could harness the glucose in blood and saliva. It then converts that glucose into enough electrical energy to power an average consulting room in a doctor’s office.

Technology like this will change biomedical waste management drastically. It’s not just about how to safely destroy biomedical waste anymore. You need to be able to harness the energy produced from this process in order to create a more sustainable disposal process.

Tracking Medical Waste

People are getting informed about the dangers of biomedical waste. Climate change is a hot topic. Your patients and employees are likely going to have read how waste not properly disposed of can be extremely harmful to the environment.

This makes the transparency of your biomedical waste management process so vital. You want to stay informed about where your biomedical waste is going and how it is being disposed of.

Many biomedical waste management companies work with third-party companies that cannot always be trusted.

Thankfully, United Medical Industries provides a complete end-to-end, fully tracked medical waste process. Waste removed from your hospital, lab or office never leaves UNI’s hands.

Steam Autoclave Technology

Incinerating biomedical waste is an archaic method still used by many medical waste management companies. Incinerators produce hazardous and combustible air pollutants like hydrochloric acid and carbon monoxide.

These gases are incredibly harmful to the environment. This is why UMI uses an autoclave system that uses steam to sterilize hazardous biomedical waste.

Autoclaves are an insulated pressure chamber which uses saturated steam to elevate the temperature in the chamber. Using steam is both cost-efficient and eco-friendly. The only natural resource you’re using is water vapor and there are no harmful chemicals produced using this process.

Keeping Up With Changing Regulations

The Department of Environmental Protection has strict rules when it comes to biomedical waste and pharmaceutical waste. These regulations are subject to change from time to time as well.

It’s critical you keep up with these regulations and make sure your facility is in full compliance. This can be tricky if you’re not extremely familiar with all the rules.

For example, pharmaceutical waste needs to be contained and handled in a very specific way. The best way to make sure you are doing things by the book is to check with your biomedical waste management company. It’s their business to stay up to date with these regulations.

UMI provides proper pharmaceutical waste collection containers and will be able to instruct you on the right way to use them.

Make Sure You Are Certified

The facility’s that deal with medical waste need to make sure they have certified annually with OHSA. UMI offers OSHA BBP Training that will satisfy the annual OSHA Bloodborne Pathogens requirement. UMI will also help you identify health, safety, and fire hazards that may exist so you can correct them before your OSHA audit.

Converting to IDC-10

The International Classification of Diseases is a clinical cataloging system that the U.S. healthcare industry uses to record diseases on health records, track epidemiological trends and assist in medical reimbursement decisions.

Recently, the tenth edition of the IDC was published in order to account for modern advances in medical devices and treatments.

IDC-10 provides more detailed coding that can help improve the reporting on new medical advancements and the way payments are processed in the healthcare system. However, this new platform comes with some changes.

For one thing, IDC-10 has 50,000 more codes in it than the previous version, IDC-9.

The transition to IDC-10 is still recent and adopting all that new coding into everyday practices can be a rough transition. However, mastery of the new system could greatly improve your hospital or lab’s ability to provide and report on the best medical treatment.

UMI offers services that make the transition from IDC-9 to IDC-10 as smooth as possible. You will be able to bookmark, search and print all relevant codes as well as reduce billing errors and rejected claims.